Finishing & Embellishment

TP‑702NIL Cross Strapping

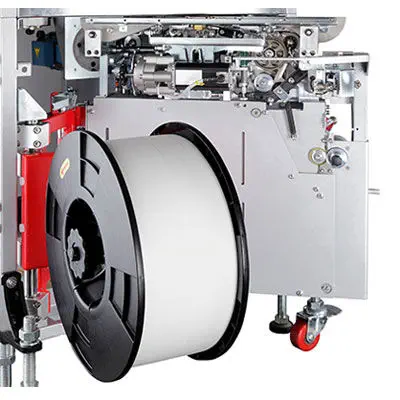

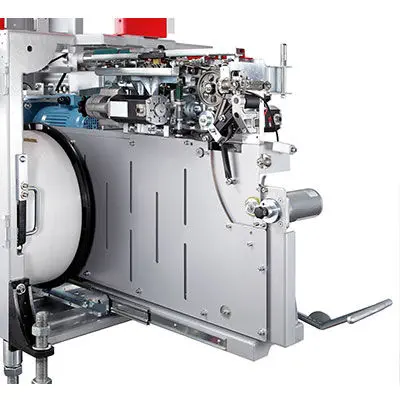

The TP-702NIL is a fully automatic inline cross-strapping machine engineered for efficient, high-speed bundling. It handles a wide range of bundle sizes (from small stacks to bulky loads up to 25 kg) and applies polypropylene straps (5, 6, or 9 mm) with adjustable tension. Designed with a compact strapping head, programmable PLC control, and pneumatic pressing, the TP-702NIL ensures secure, fast, and consistent strap binding — making it ideal for print shops, mailing houses, packaging lines, and production environments requiring automated bundle strapping.

Brand

Transpak

Models

Product Specification

TP‑702NIL Cross Strapping

| Operation Type | Fully automatic inline cross-strapping |

| Throughput (Speed) | Up to 31 bundles per minute |

| Bundle Size — Width | Min: 120 mm — Max: 450 mm |

| Bundle Size — Length | Min: 210 mm — Max: 500 mm |

| Bundle Size — Height | Min: 10 mm — Max: 390 mm |

| Maximum Bundle Weight | Up to 25 kg |

| Strap Width Supported | 5 mm, 6 mm or 9 mm polypropylene (PP) strap |

| Tension Range | 1 – 32 kg (adjustable) |

| Power Supply / Electrical Requirements | 220V / 380V / 400V / 415V — 50/60 Hz — 3-phase (depending on configuration) |

| Compressed Air Requirement | 6 bar pneumatic source |

| Air Consumption (per cycle) | Approx. 11.18 liters per strapping cycle |

| Control System | PLC with HMI interface for automatic operation and adjustment |

| Strapping Head | Compact mechanical head with self-adjusting strap chute |

| Bundle Handling | Cross-strapping without bundle turn; dual pneumatic press; automatic strap ejector |

| Optional Features / Accessories | Soft-press option for uneven bundles, adjustable working height (730–830 mm), light-tower with low-strap sensor, mobile casters, automatic side-squaring, bypass for low-volume bundles, reverse bundle flow |